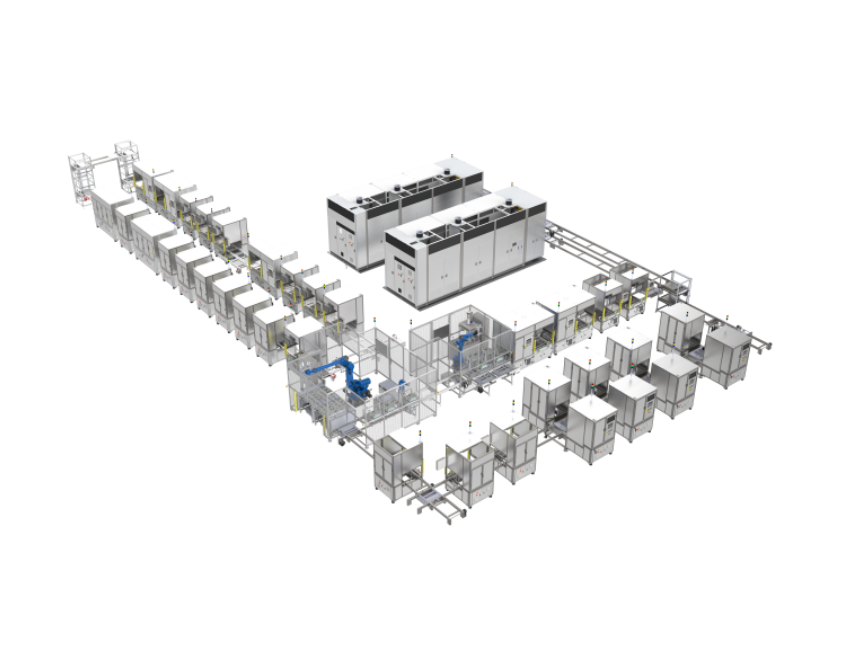

The fully automated flexible production line consists of multiple standalone units connected in series, integrating automatic loading/unloading, assembly, dispensing, potting, curing, testing, and aging processes. It offers high reliability and process compatibility, enabling efficient coordination between high and low payloads. Equipped with a visual dashboard system, it monitors and records real‑time data throughout the entire process, supporting quality traceability. With a flexible quick‑change design, product models can be switched rapidly through simple adjustments.