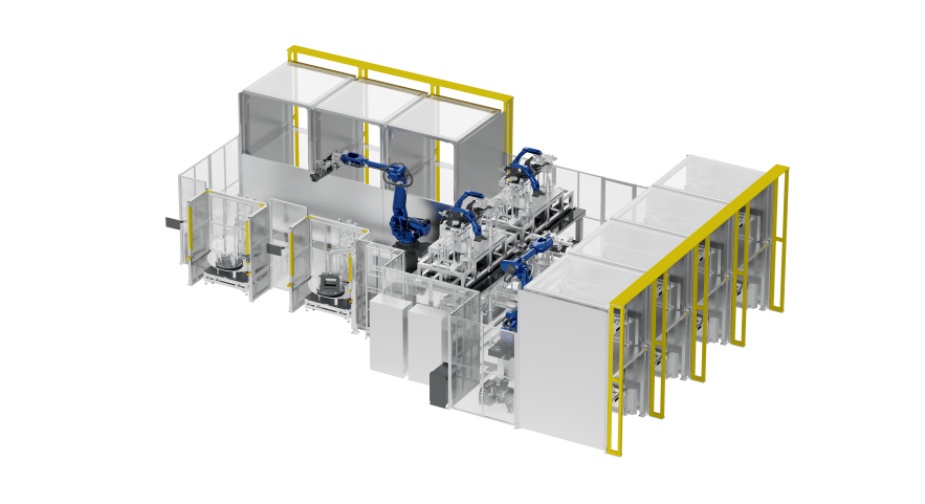

The visual inspection system integrates industrial cameras with AI algorithms to automatically detect and classify various surface defects such as cracks, sand holes, and pores. It is suitable for both full inline inspection and offline sampling on casting production lines, significantly improving inspection efficiency and consistency. The system supports real-time defect data storage and traceability, facilitating quality optimization and digitalized quality management.